- Built From The Ground Up

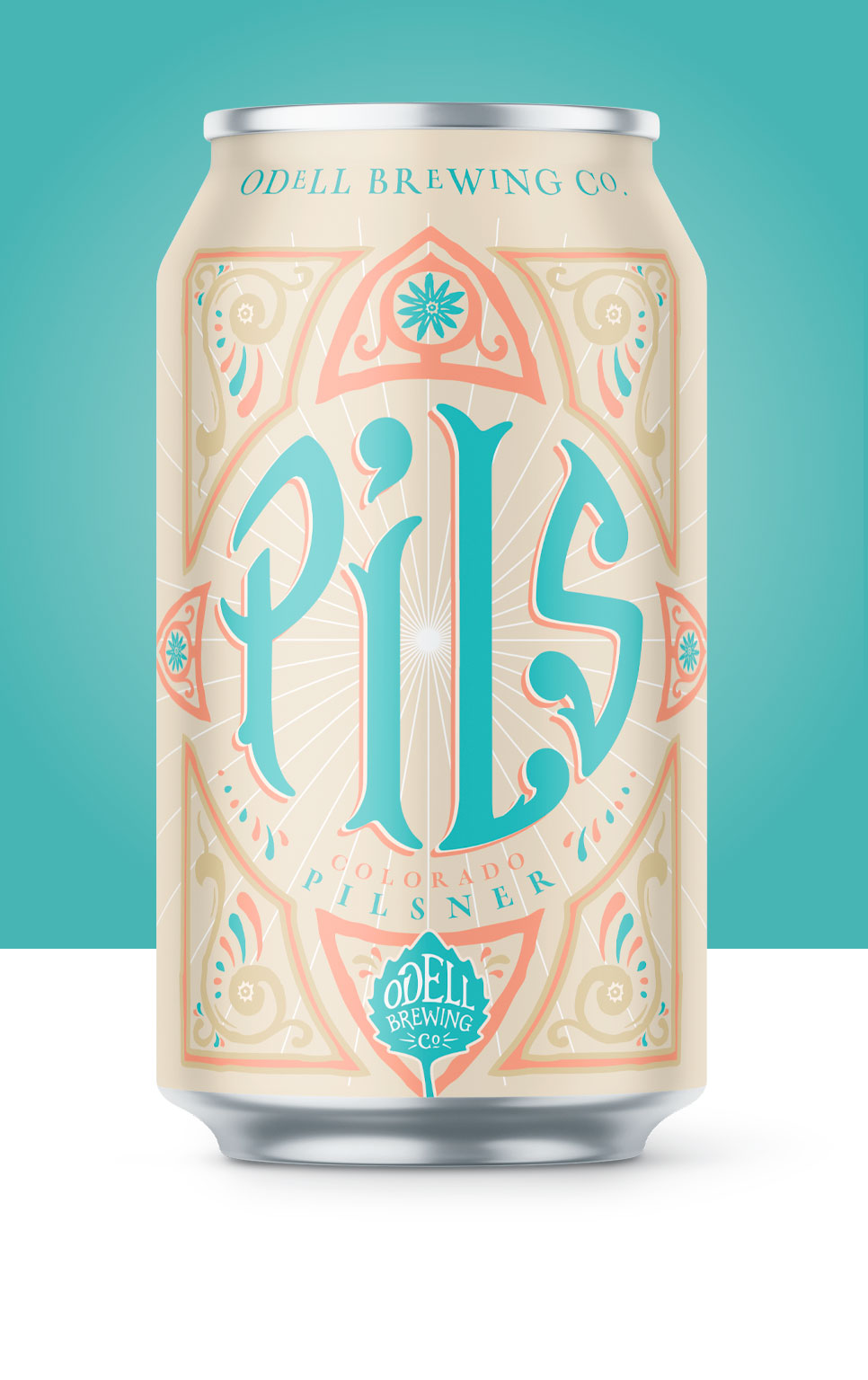

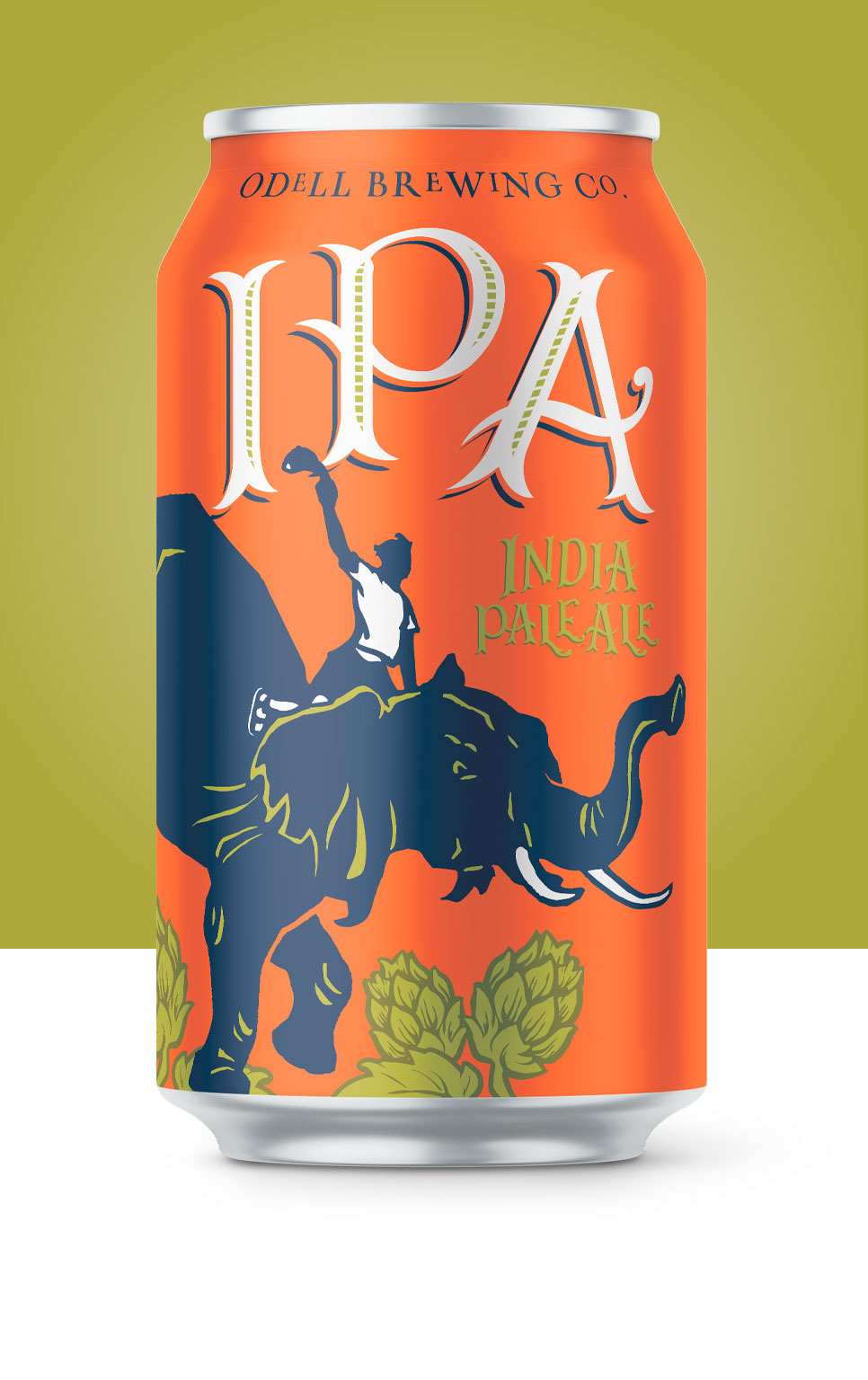

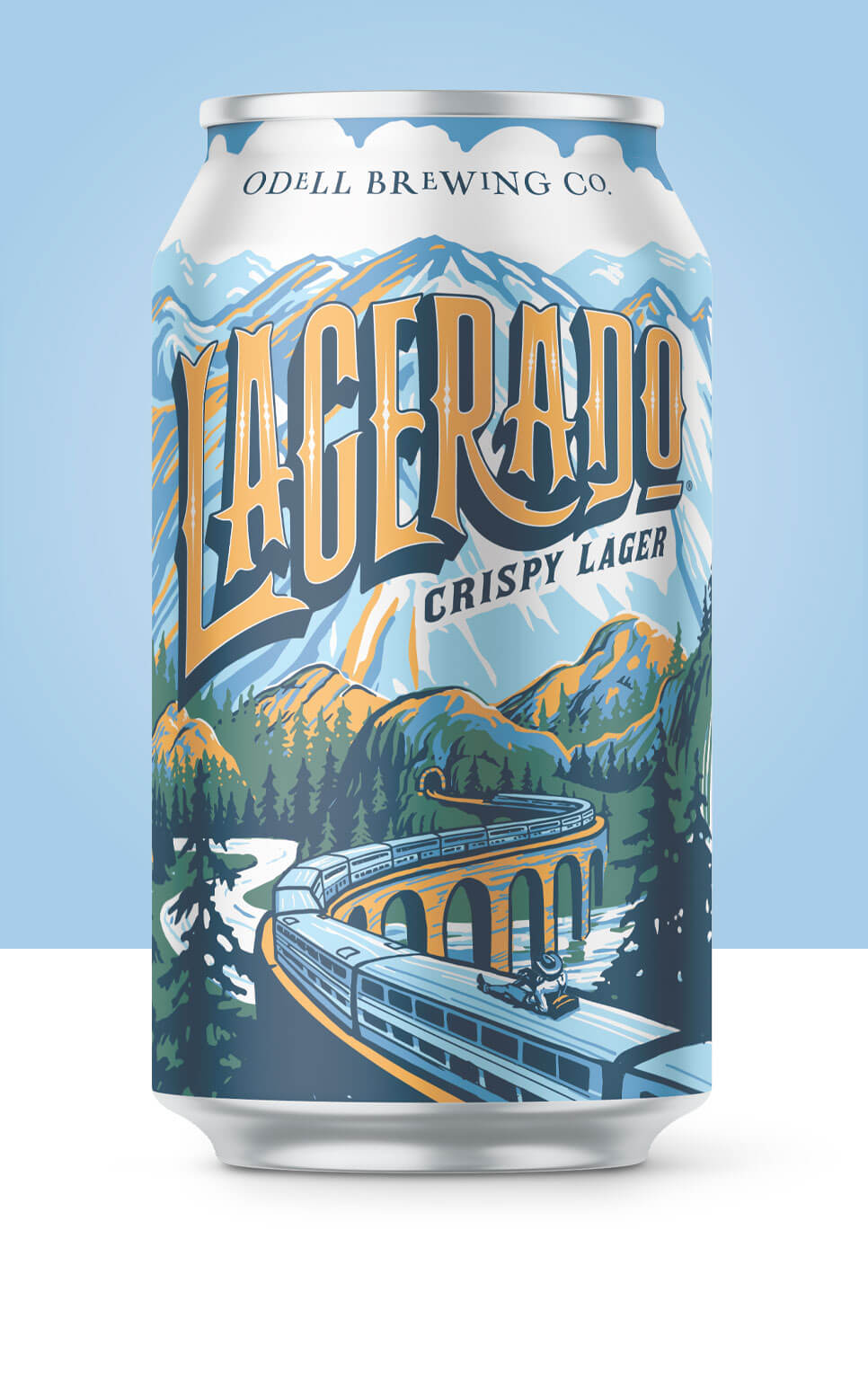

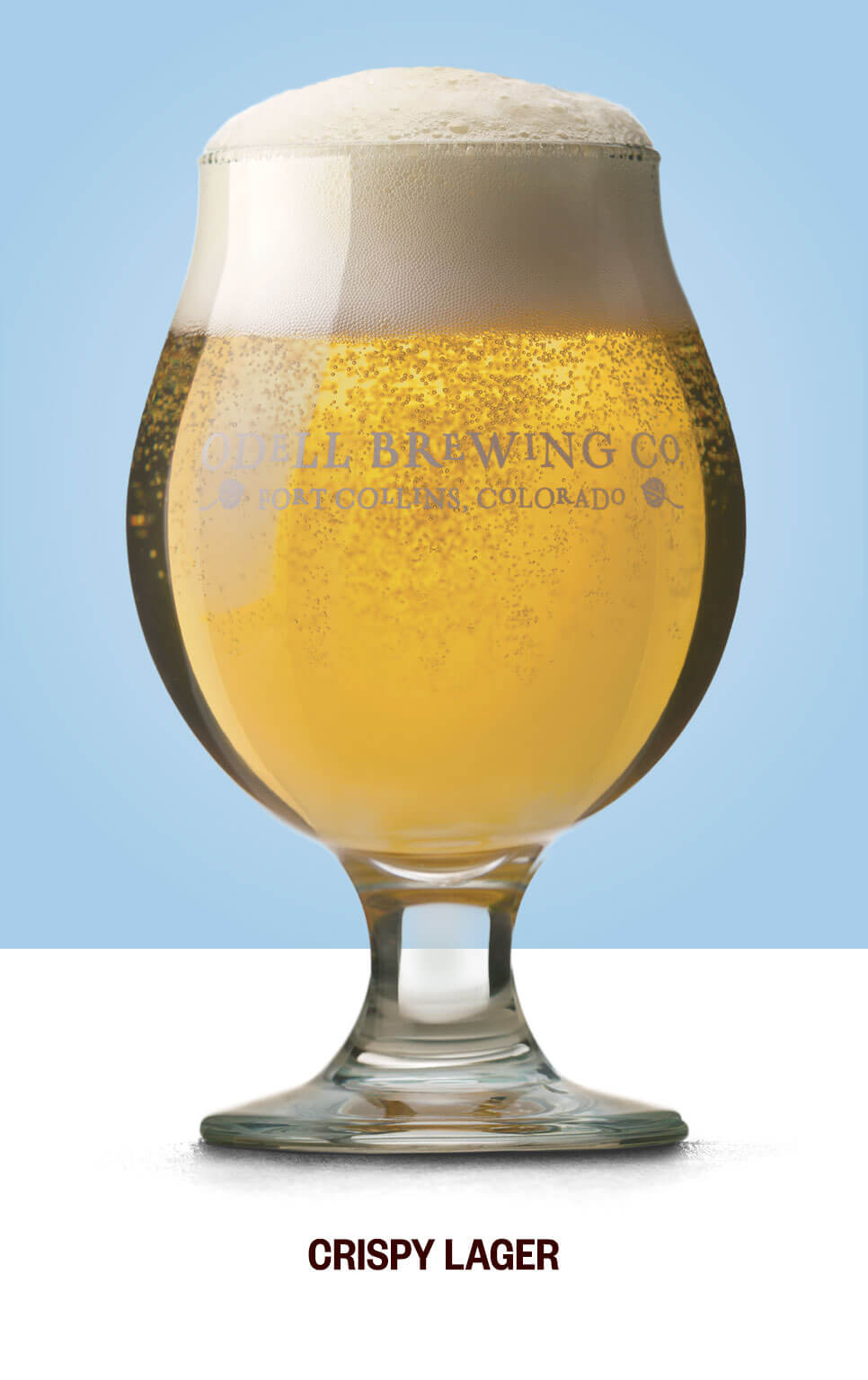

Our Craft & Our Culture

Proudly Colorado

With the Rockies as our backdrop, Colorado has always been home. Visit our flagship brewery in Fort Collins or our Denver small batch brewhouses in the Five Points and Sloan’s Lake neighborhoods.